Small Boats - Geelong

Starting out with a sketch

Life for this boat started on a piece of paper. After much sketching, rubbing out, redrawing, I moved onto the computer to create the hull in 3D. The design process involved careful consideration of the boat's unique characteristics.

Marking out the wood

Once I was happy with the 3D model, I created templates with dimensions for each of the hull panels and transferred them onto the plywood. This careful marking process ensures precise construction.

Assembling the pieces

This boat is almost as long as your car at 4.7m (15.4 ft), so I needed to scarf 2 sheets of ply together to cut the parts from. The assembly process required careful alignment and temporary fixtures.

First time in the water

As soon as the epoxy had dried, I was off to the water to see it float. It sat on the water rather than in it. I got in, but without the outrigger it was very unstable!

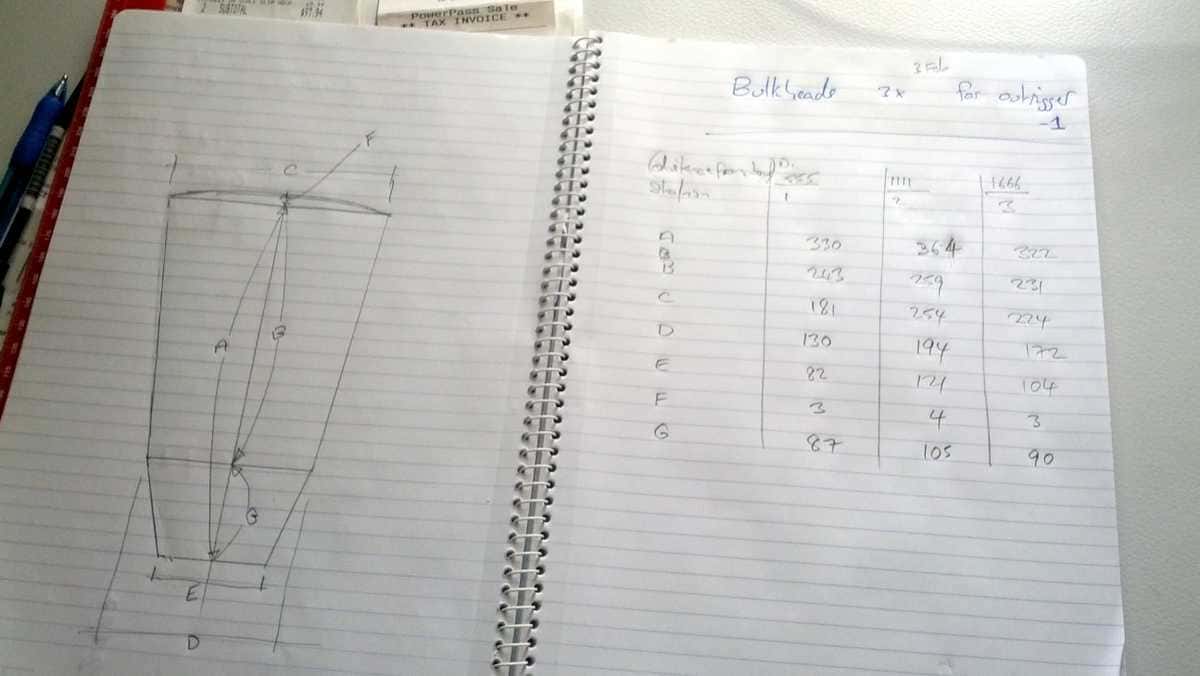

Building the outrigger

The outrigger is crucial for stability. I constructed it using the same techniques as the main hull, with careful attention to the connection points and buoyancy distribution.

To the water - for real this time

I lived only 1.5km (1 mile) from where I could launch the boat, so I walked her to the water. It is surprisingly easy to pull, using a homemade wooden trolley with cheap inflatable wheels. Once at the water's edge, it took about 10 minutes to rig and we were sailing.

The building trolley

A simple but effective solution for transporting the boat. The wooden trolley with inflatable wheels makes it easy to move the boat from home to water, even over rough terrain.

Build and Sail

Sailing doesn't get much cheaper than this. The outrigger design provides excellent performance and stability, making it perfect for coastal cruising and day sailing.

Build GeelongConstruction details

The construction process involved careful attention to detail, from the initial hull assembly to the final finishing touches. Each step was documented to ensure quality and repeatability.

Finishing touches

Sanding and finishing the hull is crucial for both appearance and performance. The smooth surface reduces drag and makes the boat easier to maintain.

The completed boat

The finished boat represents months of careful work and design refinement. The result is a seaworthy, efficient sailing vessel that can be easily transported and launched.

Ready for adventure

The Little Proa is now ready for countless hours of sailing enjoyment. Its simple design and reliable construction make it perfect for exploring coastal waters and enjoying the freedom of sailing.