Boat building with a CNC router

30 June 2017

First published - 30 June 2017

For those lucky enough to have a CNC machine in the workshop – this is the way to scarf and cut your plywood!

Andre, from Melbourne, Australia, is building the small boat “Noosa” in his workshop and sent me these photos of his progress so far. He’s kindly let me share them with you.

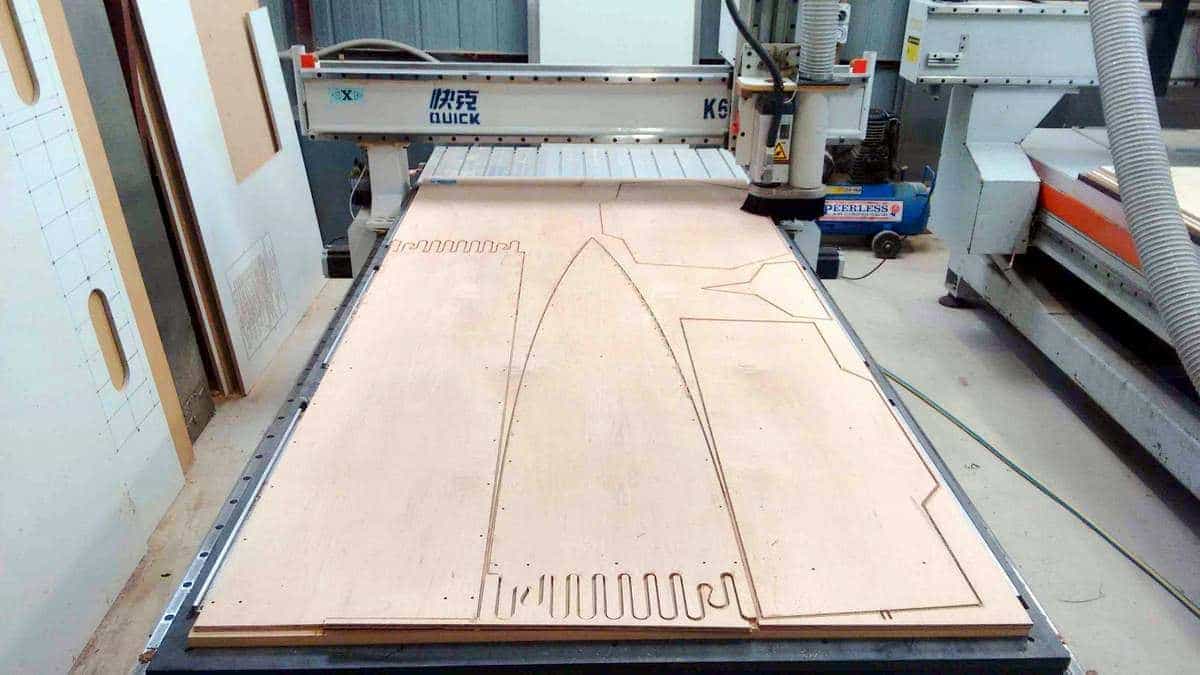

Andre’s got a CNC router in his workshop and decided to put it to work on his boat. It was his first time cutting plywood with the machine, so there was a bit of setup and learning to do at the start. But once everything was dialled in, it took just two hours to cut every part of the boat.

Using DXF files skips several jobs completely:

-

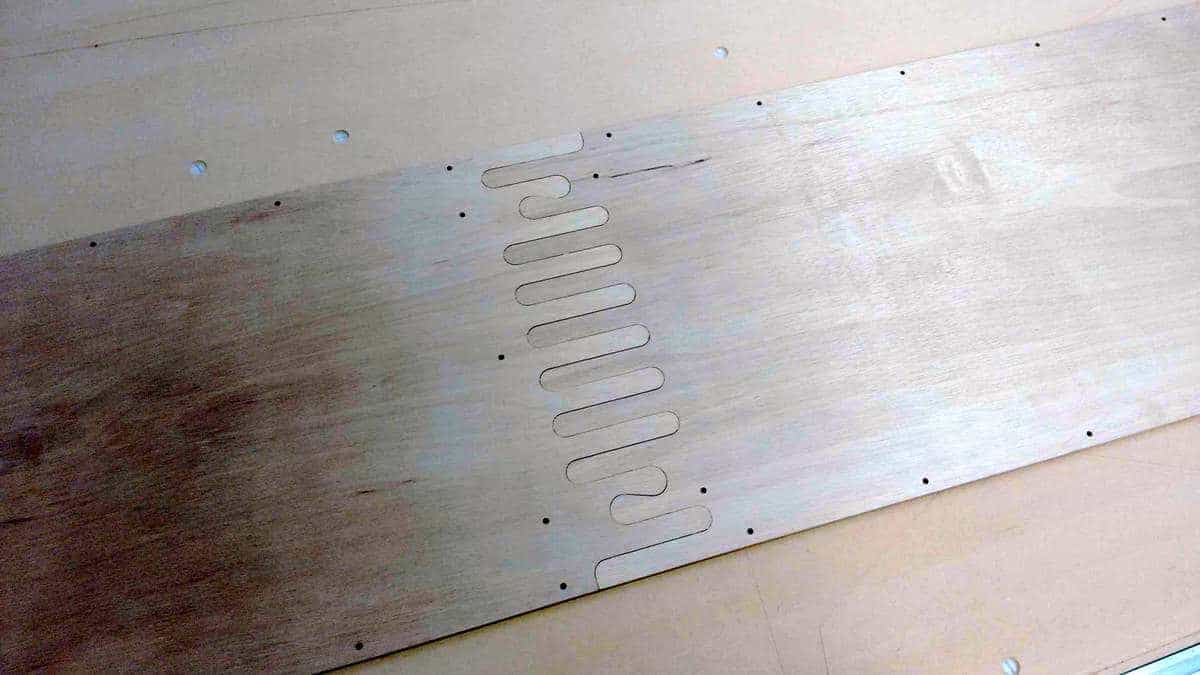

No scarfing plywood sheets beforehand. For hull parts longer than a standard panel, the CNC cuts them into sizes that fit the plywood sheet or the machine bed. Finger joints are cut into the ends so they can be joined later. No grinding feather edges, no wrestling full-size sheets into place. Honestly, scarfing was always a job I was happy to get behind me. Plus, this method often makes better use of your plywood.

-

No drawing parts onto the plywood. The DXF file tells the machine exactly where to cut. That means no measuring, marking, joining dots, or tracing shapes. No battens, no lofting, no mistakes.

-

No hand-cutting along the lines. Another time-consuming step gone. The CNC does it faster than you can—and more accurately. Every part comes out spot-on in shape.

The precision is brilliant, as you can see in Andre’s photos. Hats off to him—great work.

Now, I’m not suggesting you’d buy a CNC router just to build a small boat like Noosa. But if you already have access to one, or know someone who does, it’s a great example of what’s possible these days—even at home. I’ll admit, I’m a little jealous. A CNC router is firmly on my wish list for my next build.

Like 3D printers, CNC routers are getting cheaper and better almost by the day. There are also DIY kits and plans to make your own, which means you can get industrial-level precision in your shed. For something like a big yacht project, this sort of tool isn’t just handy—it’s edging into “essential” territory.

Cutting intricate plywood shapes is one of the bigger time sinks in any build, small or large. From temporary hull frames and hull panels to bulkheads and interior joinery—it all takes hours if done by hand. CNC removes the need to print or plot from drawings, trace them onto wood, and then cut them out. With digital files, you just send the shape straight to the machine. No fuss, no wasted effort.

Update – 12 April 2019: Things move fast. It’s nearly two years since I first wrote this post, and back then I’d only get the odd enquiry about CNC files. Now, I get them almost every week. So, from this week onward, CNC files are available as an optional extra with any plans on this website.

There’s still a learning curve, and some setup time, but once you’ve got the hang of it, CNC can save you a lot of time—and everything comes out perfect.

Great work, Andre. 👏

Thanks for reading,

Tim Weston