Select Page

No problem… Build your next boat now, without a shed. This boat you can build in your living room.

At 850mm (33″) long it’s a perfect size to assemble on the dining room table. Designed to be built from economical, easy to source materials such as plywood, cardboard or plastic signboards.

Get the same satisfaction as building larger boats—transforming flat bendable panels into a rigid 3D form, as you bond them together to form the hull. Even with cardboard. Enjoy boat building on a smaller scale—inexpensive, quick and fun.

Print the full-size plot templates on any A4 printer. Tape the overlapping sheets together. Tape the sheets to the ply or cardboard and easily trace out the full-size shape of the hull parts. No measuring required.

Cut out the parts, glue them together with hot glue, and within a few hours be holding a hull in your hands. It’s magic. I never thought I could have so much fun with cardboard…

To cut the hull parts from ply or cardboard, 1:1 full-scale plots are included in the plans to save you time measuring. Print the templates with a regular A4 paper on your printer or at the local print shop. They are coded and marked to align perfectly. Tape them together, to form the full size pieces.

Pin or tape the joined sheets onto the wood or cardboard and use a sharp knife or dressmakers wheel, to mark through the paper into the material.

All the parts are clearly labeled. When building with cardboard, use a serrated steak knife to cut along the dots. It makes a clean cut through the material and only takes minutes. Now, plug in your hot glue gun and start gluing everything together.

this is what I ended up with. Still lots more to do, but it was quick to cut out and glue together. Cardboard is a great material, it’s structural, it’s everywhere, and it’s free!

There are plenty of notes with the drawings and in the build notes, to get you started. Also a material list of the major materials you need (not much) to build. With a coat of outdoor paint, she will soon be ready to go sailing.

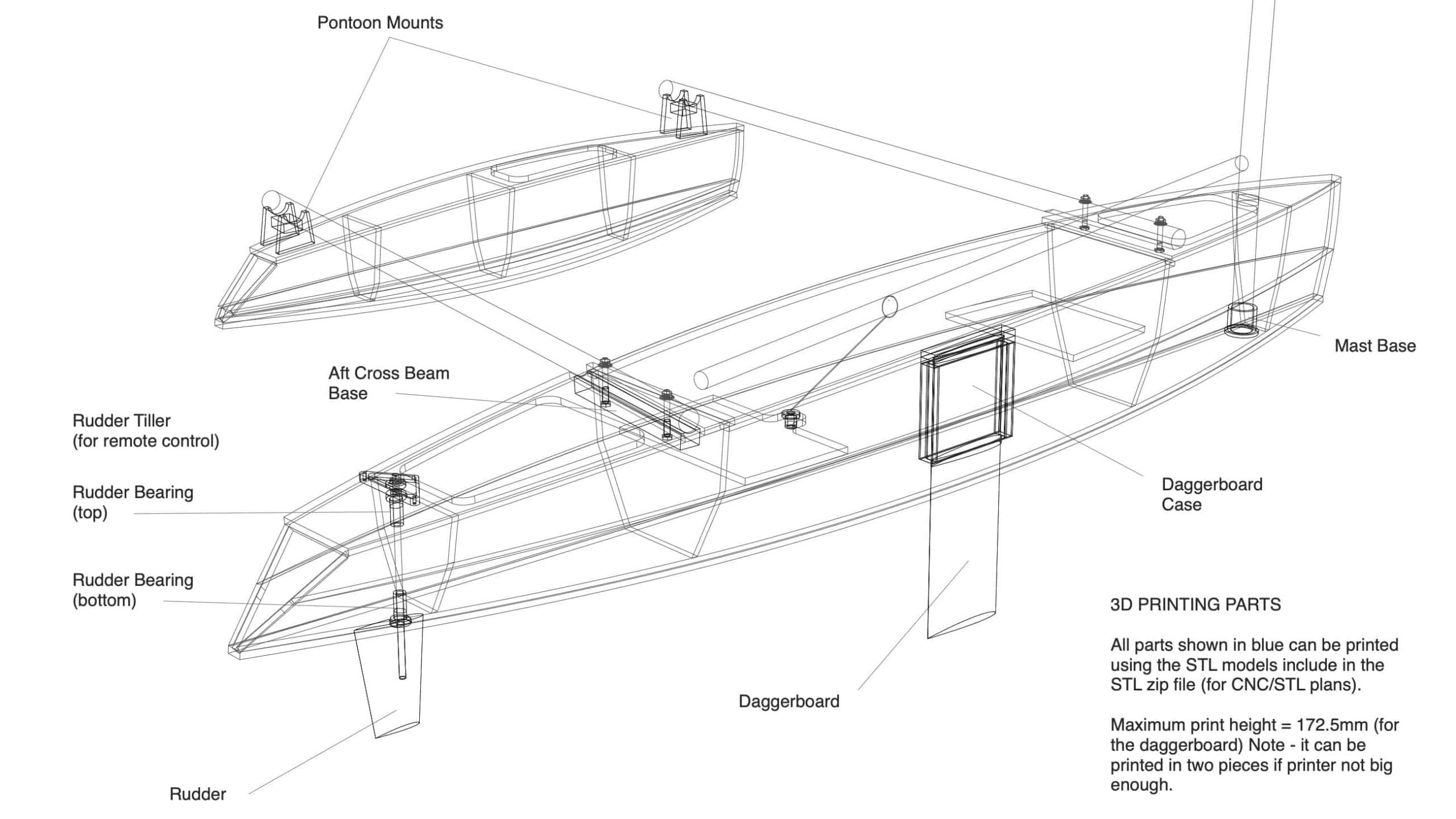

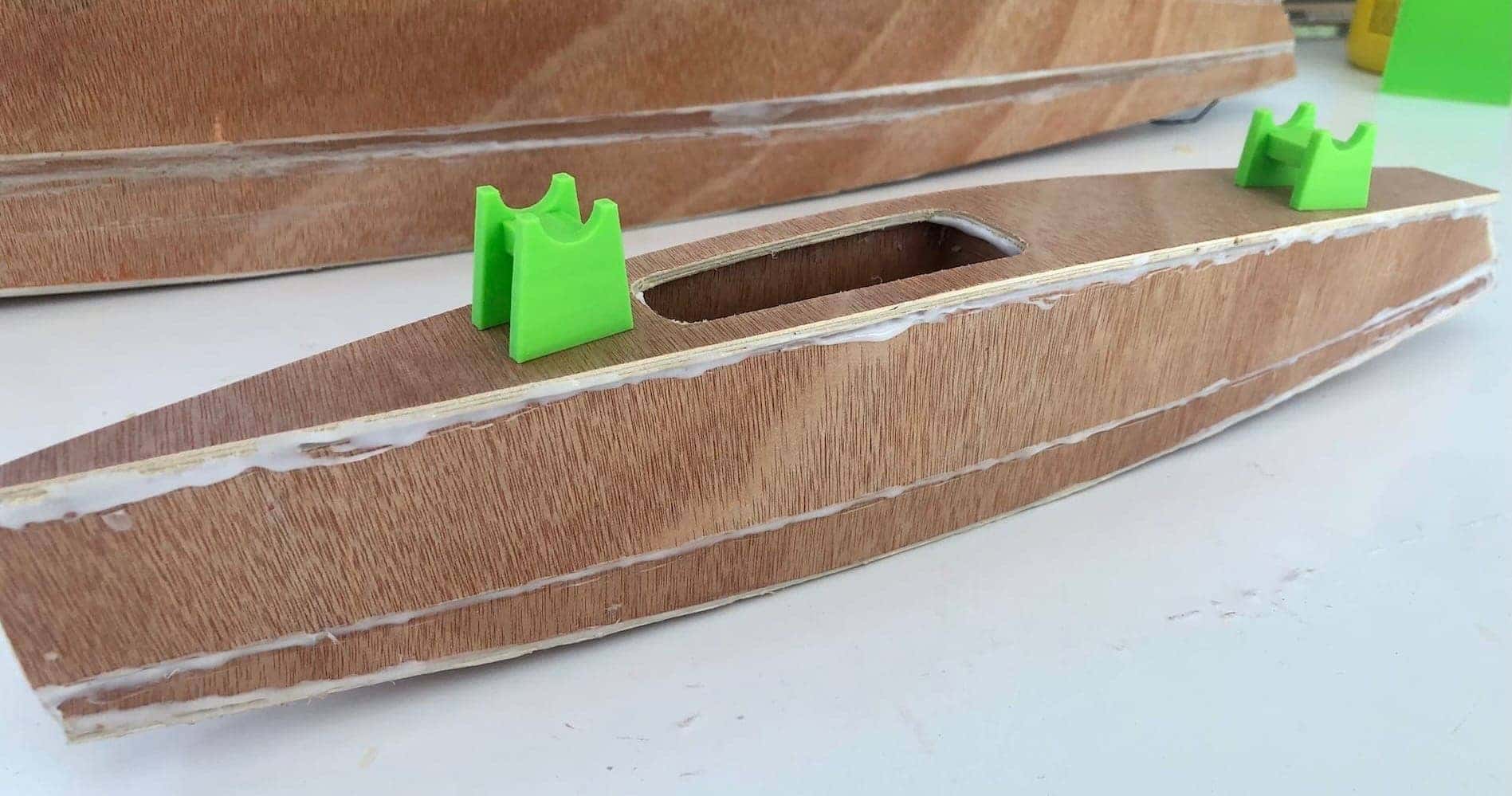

if you have a 3D printer or access to one or a print service, choose the Full Plans + CNC/STL. The plans include STL models to print the rudder, daggerboard and the other fiddly bits.

The plans also include DXF files to CNC cut all the plywood parts (see photo below). If you don’t own or have no access to either of these machines – no problem. These parts can all be made from wood, plastic or nylon. Dimensions for cutting and suggestions on ways to do it are in the plans.

If you are using a 3D printer, a model for the rudder is included in the plans. Use a 3mm (1/8″) stainless steel metal thread as a shaft. Bond the 3D printed bearings into the holes in the deck and hull bottom. Fit a short piece of 6mm (1/4″) plastic hose (or a straw) between the bearings to keep the water out!

If you don’t have a 3D printer or access to one, not a problem. Find some thin plastic tube or hose (or even a plastic straw) that runs from hull floor to deck. Bond in place with hot glue. If the diameter is too big for the shaft, fill the ends with hot glue and drill through the glue once hardened with a drill slightly larger than the rudder shaft.

This boat is made to use, not just put on the mantle piece… Electronics are cheap, order a low priced remote control from somewhere like Hobby King or Amazon and go sailing! The minium is a single servo/channel RC, to steer the boat. The tiller in the plans is designed for remote control steering.

I build large daggerboards into all my boats. I am passionate about using the wind, to go to wind, and a model is no different.

The plans include an STL model, for a large daggerboard and, dimensioned drawings to make from plywood if you don’t have a printer.

When sailing with remote control, this boat is designed to sail upwind, as well as down wind. So you shouldn’t lose it!

Credit and thanks to Olivier in Tahiti, for kindly allowing me to show some of his work – building in plywood with his 3D printer and CNC machine.

2022©timwestonboats.com